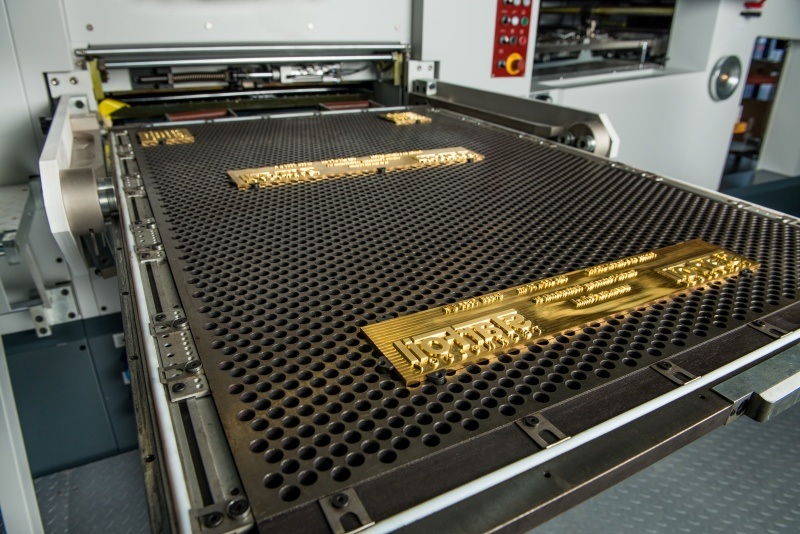

Die-Cut, Foil and Hot Stamping

PETRATTO PDF74

- Max sheet size: 740 x 530 mm (B2)

- ● Min sheet size: 420 x 297 mm (A3)

- ● Paper/carton board thickness: 80 - 500 g/m²

- ● Corrugated board thickness: 1.8 mm (80 pts)

- ● Grippers margin: 6 - 20 mm (0.25 - 0.8 in)

- ● Max pressure: 100 t (x 5)

- ● Max speed - sheets/h (multipositions/h): 1500 (~ 5000) c/h

- ● Automatic size adjustment: Yes

- ● Registration through print marks reading: Yes

- ● Multiposition system max.: 10

- ● Pressing time adjustment: Yes

- ● Pressing cycle repetition: Yes

- ● Machine dimensions: L 2.7 x W 1.5 x H 1.8 m (L106 x W60 x H70 in)

- ● Machine weight: 4.5 t

STARFOIL 106-HS

automatic hot-stamping, embossing and die-cutting press with Mabeg feeder

• Mabeg feeder for efficient material feed and thin paper

• Accurate and durable drive chain

• Equipped with 5 foil pulls

• Equipped with 3 hologram registration units + software

• Servo motors for foil pull and main clutch

• Control panel and software

• 300mm raised frame with higher capacity in feeder and delivery

Machine - main characteristics

• Sheet size: 1060 x 760 mm

• Three operator panels, one for controlling foil system and two for controlling the machine

• Maximum mechanical speed 7500 impressions per hour

• Complete electric & electronical system

• Fully automatic oil system for both main machine and drive chain

• Self diagnosis system with indication on the screens

• Lock for the gripper bar can be micro-adjusted

• Gripper bars are made of special industrial aluminium with hardened grippers

• Full sheet detection throughout the machine

• Linear scale throughout the machine, both for paper and foil inspection

• Robust construction

• Pneumatic accurate main clutch

• Automatic impression on and off by servo motors

• Precise and accurate drive of the table

• Calibrated top table

• The chase is locked pneumatically

• Height of the table is indicated in millimetres

• Main drive chain equipped with security clutch

• Operator's platform with steps and guarding

• Sheet inspection table with top lighting

• Precise, controllable and consistent pressure

• Fitted with the Mabeg feeder

• Standard 300mm raised frame for higher feeding and delivery capacity

• With table to prepare foil shafts outside the machine

• Equipped with E-stops

• Complies to CE norm.

Feeder section

• Mabeg feeder for quick set up and excellent for light weight paper as well as board at maximum speeds.

• Paper range from 90 grs. - 2.0 mm

• Non stop feeder system is standard and offers efficiency for long production runs

• Double sheet detection

• Push and pull side lays (operator and non-operator side)

• Electronic side lay control

• Two electronic front lay controls

• Possibility to adjust timing of the inlay

• Press bar

• Safety during lowering the feeder table

• Position of the feeder table can be adjusted during production

• Becker Vacuum pump for feeder included

Delivery section

• Automatic non-stop delivery is standard. The carpet moves in and out during production automatically

• Brushes in delivery for sheet slowdown

• Equipped with side and back pushers

• Security during lowering of the delivery table

• Paper insert device (included)

Foil section

• Air foil separator suitable for large full area stamping

• Blower unit to stabilize the sheets

• Automatic impression throw-off

• Device to feed new foil into the machine

• Equipped with shafts for foil converting with knives for foil slitting

• 5 independently programmable foil advance shafts

• 3 hologram registration units for printing registered holograms

• Servomotors to control foil pulling

• Programmable foil pulls and steps for foil advance optimization

• Possibility of preparing the foil rolls on the shafts outside the

machine for installation into the foil module (table included)

• Programs can be stored in the central PLC

• Adjustable dwell time

• Timer

• Equipped with evacuation brushes for wasted foil

• Fitted with 20 digital heating zones controlled by Siemens PLC

• Detection system for foil breaking (12 units)

• Foil run out warning

• Inner foil core diameter can be 1" (25 mm) or 3" (76 mm)

• Machine can take up rolls as narrow as 20 mm without problems